An In-Depth Look at How AST Equipment Helps You Produce Quality Results

In our first blog post of the year, 5 Ways AST Can Help You Reach Your Business Goals in 2022, we described five ways that AST and AST equipment can help your business. In this post, we are going to dive further into the first way, which was getting quality results.

Quality results, in this case, is referring to the quality of the texture that you are spraying on the wall. You’ve probably walked into a house before and not been impressed by the texture on the walls. Maybe it was too thick. Maybe it was too thin. Maybe the dots were too big or too small. You might even see areas where the material wasn’t atomized and “blobbed” onto the wall, creating an inconsistency in the pattern.

Your trained eye probably notices more imperfections than the average homeowner, but someone moving into a new house or checking out the renovation they are paying for is still going to notice if the texturing job isn’t done well.

As a texturing contractor, your goal should be to produce texture that is consistent and beautiful throughout the entire project. To do this, you need a machine that is capable of producing those consistent and beautiful results. An AST big rig texture sprayer is ideal for achieving these results.

There are multiple ways a big rig helps you:

Mix One Batch of Texture

You can mix texture for the entire project in one batch in the large tank. Tank sizes on gas-powered big rigs range from 150 to 350 gallons so you can get a big rig with enough capacity, even if you spray huge projects.

The consistency that texture is mixed to is one of the things that affects the final pattern. Thicker material will produce heavier texture and thinner material will produce lighter texture. It is possible to mix and spray separate batches and get similar results on the wall, you just have to make sure you mix with the same amount of water and for the same length of time for each batch to ensure the consistency is the same.

A big rig makes this process much easier by eliminating multiple batches. You won’t have to worry about mixing multiple times if your tank is big enough to handle the material for an entire project.

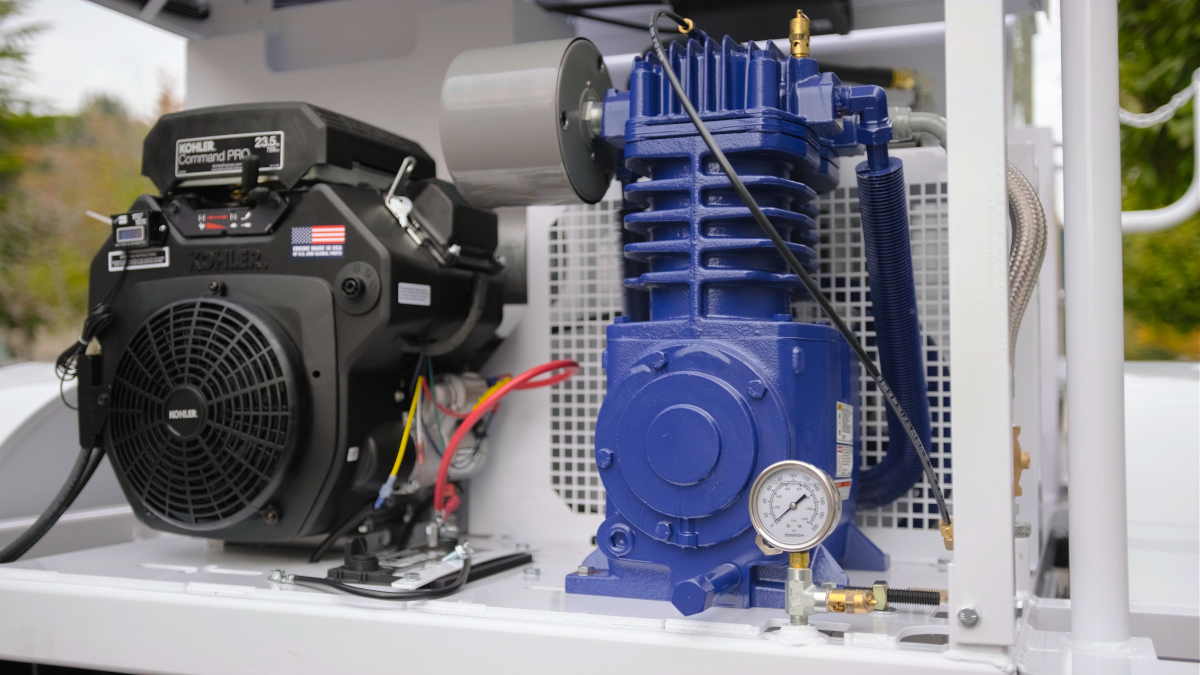

High CFM Compressors

We use Kohler motors on our big rigs. The base model spray rig uses a 20.5 HP engine and you can upgrade this to a 23.5 HP motor. We use these motors because they are capable of spinning the paddles when you have a tank full of mud, but also because they are capable of powering high CFM compressors.

The standard compressor on spray rigs is 23 CFM and you can upgrade to a 35 CFM compressor. That is a huge amount of air at your disposal. For reference, your typical high end two-stage wheelbarrow style compressor might be able to produce as much as 17 or 18 CFM. Even 17 or 18 CFM would give you quite a bit of capability, so you can imagine that 23 CFM, or even 35 CFM, would mean you have zero limits.

What does high CFM do for you? It gives you options:

- You can turn up your pump speed and air and move through a house faster

- You can spray finer patterns by turning your air up

- You can put in a bigger tip and turn up your air to spray more volume

You don’t want to be held back by a low CFM compressor. High CFM compressors on AST big rigs are one of the features that make these machines highly capable.

A Range of Tip Options

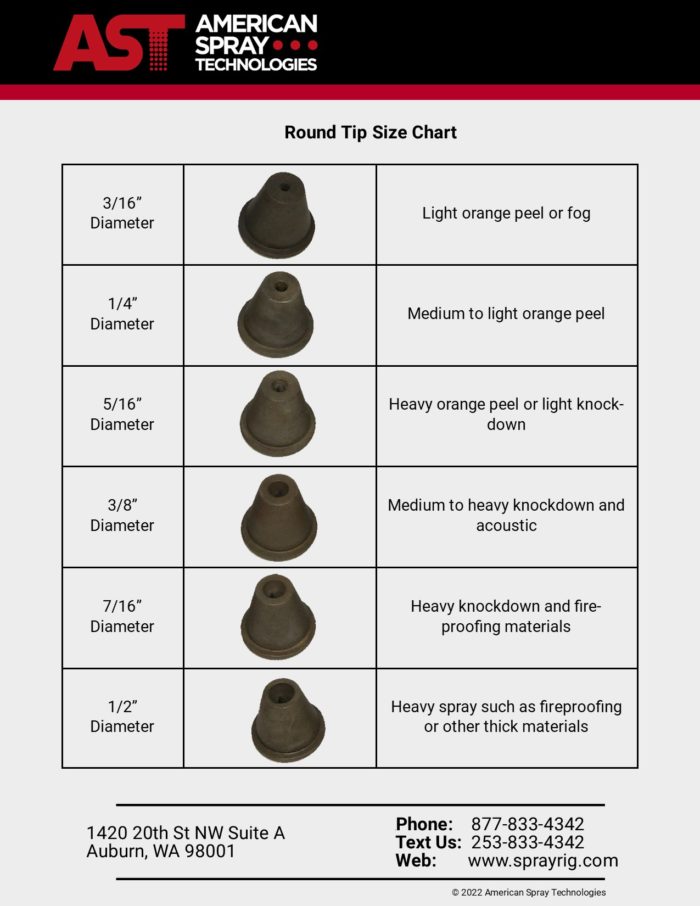

No matter what gun you choose to use, whether it be a standard Pole Gun, Flex Gun, Binks Gun, or any other available spray gun, AST carries a range of tip options for it.

Having a range of tip sizes at your disposal will allow you to get the exact texture you want. Tip size is not the only thing that affects the pattern, so you will also need to consider the thickness of your mixed mud, pump speed and air flow at the gun. However, tip size is another factor that you can use to manipulate the texture you are getting.

Smaller tips, like the 3/16” Round Tip are good for very small texture like fog patterns. The 1/4” Round Tip and 5/16” Round Tip are often used for orange peel. You can use the 5/16” tip and 3/8” tip for knockdown textures. We even have larger tips available if you’re spraying heavier materials, which are mostly sprayed in the Kodiak M2.

Hydraulic Control Rotor Stator Pumps

All AST spray rigs use rotor stator pumps, also known as progressive cavity pumps. These are the pump of choice for texturing machines because of their durability and because the performance is unmatched.

The Kohler engines on AST big rigs power the hydraulic system that turns your motor, and it is a very powerful hydraulic system. This means that your pump is capable of producing a material flow rate that, frankly, you will probably not be able to keep up with when it is maxed out. Similarly to your air flow, you don’t want to be held back by your material flow, so we make sure that is not going to happen.

Most contractors spray with their pump speeds set anywhere from 3-5, as setting it any higher would be pushing too much material to the gun, causing the sprayer to have to run through the house to keep up.

Big Rigs Are Built for Professional Contractors

If you need a texture sprayer that is built for professional contractors so you can spray orange peel or knockdown textures, an AST big rig is what you are looking for. They are built for the purpose of putting up quality, professional results job after job. There is no match for the capability of a big rig.

Hopefully this article has given you some insight into how AST big rigs help you achieve those quality results.

If you want to learn more about big rigs or to get pricing, request a quote using Build A Rig: