How Rotor Stator Pumps Work

How do AST pumps work?

AST rigs use rotor stator pumps, also known as progressive cavity pumps, because of their reliability, performance, and simplicity.

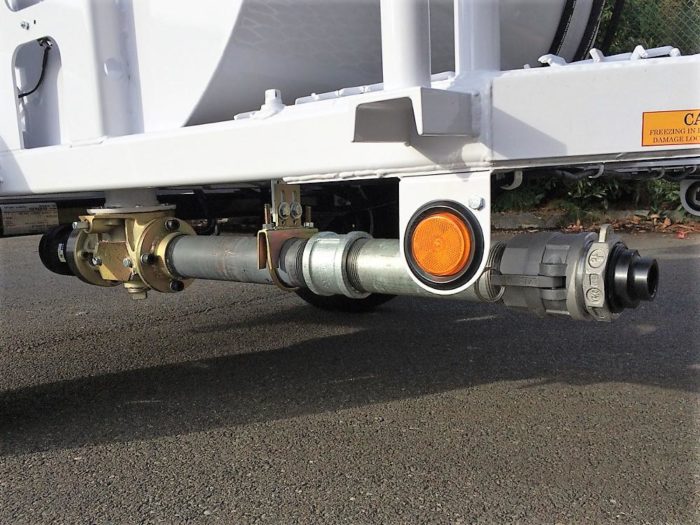

A connecting rod is used to connect the hydraulic motor to the rotor inside the pump. This system only requires three moving parts and two of them are solid pieces of metal.

How does a rotor stator pump work?

When you turn the pump on at the gun to begin spraying, the rotor starts turning inside the stator tube. Rotor stator pumps are also known as progressive cavity pumps because as the rotor turns, a series of cavities begin to progressively move material forward and it is pumped out of the pump and through the hose, eventually arriving at the gun. The tank uses gravity to feed the pump a constant supply of material to move through its progressive cavities.

Performance

Our customers like to get in and get the job done and they don’t want their rig to slow them down. Rotor stator pumps provide them with the pump speed and pressure to get the job done quickly and efficiently.

Durability

A big advantage of this pump system is the durability. Rotor stator pumps do not require all those small parts that tend to break. With proper use, rotors and stator tubes will last hundreds of hours.

Easy Maintenance

At AST we always preach ease of maintenance. You want to spray with your rig, not work on it. Rotor stator pumps are easy to service when the time comes.

Replacing parts in the pump is as simple as removing the hose using the camlock ears (no tools required) and removing the stator tube using a pipe wrench. All your pump parts are accessible after these two steps.

A sprayer familiar with the process can replace pump parts in minutes.

Spare Parts

Since the pump system in AST rigs only contains a few parts, it’s easy to keep spares around in case of an accident. Keeping an extra rotor, connecting rod, and stator tube on hand can save you time.

Next time luck isn’t on your side and you accidentally run a drywall screw through your pump, you can have a new one installed in no time at all!

Demonstration

This is not our video, but the link below will take you to a short animation on YouTube showing how progressive cavity pumps operate. Give it a watch!

For a material like drywall mud, you can’t beat a rotor stator pump. It will give you hundreds of hours of reliable performance and it could not be simpler when the time comes to replace parts. Even with no mechanical experience you will be an expert in no time!

Interested in a big rig? Request a quote by clicking the button below.