Product Manuals and Tech Support

Welcome to our tech support and product manual library! Below is an updated list of frequently asked questions, product manuals and available tech information about AST equipment. Remember, if you have any questions we have full-time support available at 1-877-833-4342.

BIG RIG MANUALS AND TECH INFO

KODIAK MANUALS AND TECH INFO

Kodiak Setup Video Series

Kodiak M2 – Pump Setup

Kodiak M2 – How to Prime the Hose

Kodiak M2 – How to Start Spraying

Frequently Asked Questions (FAQ)

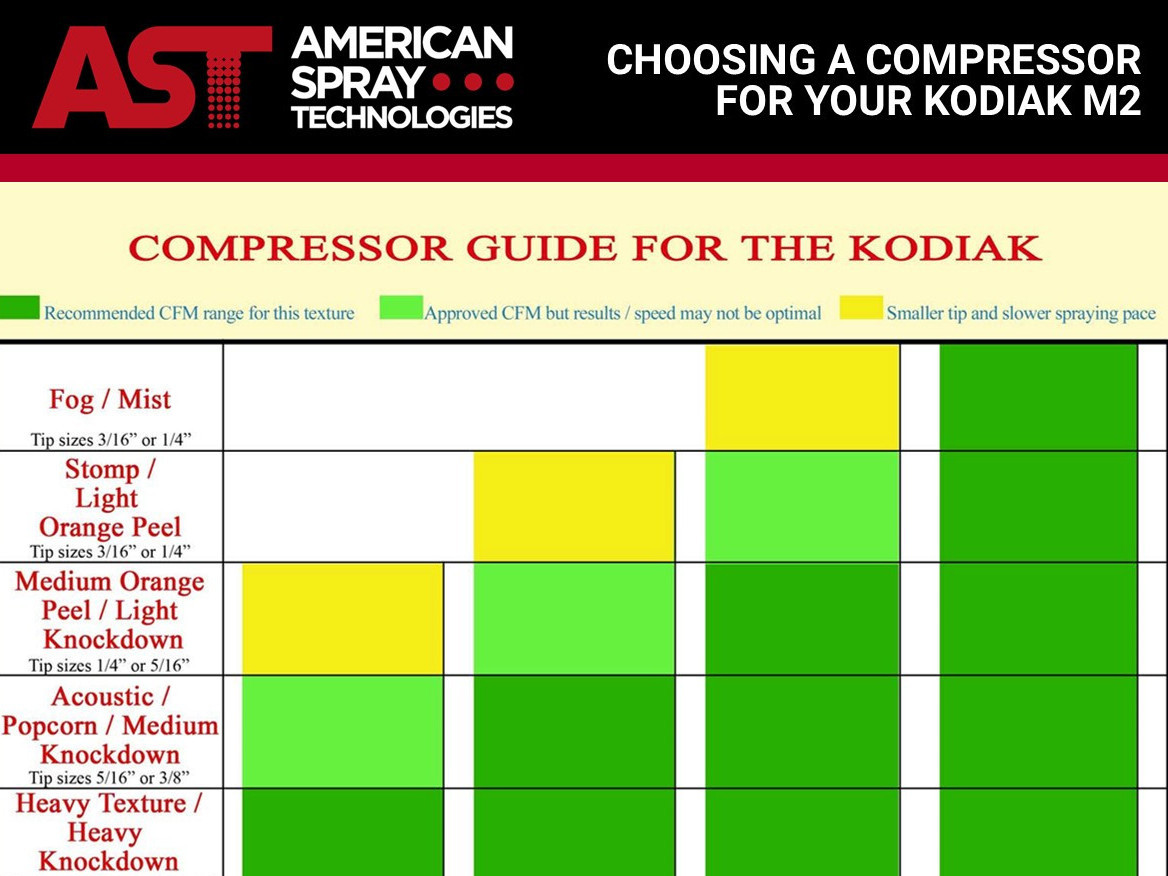

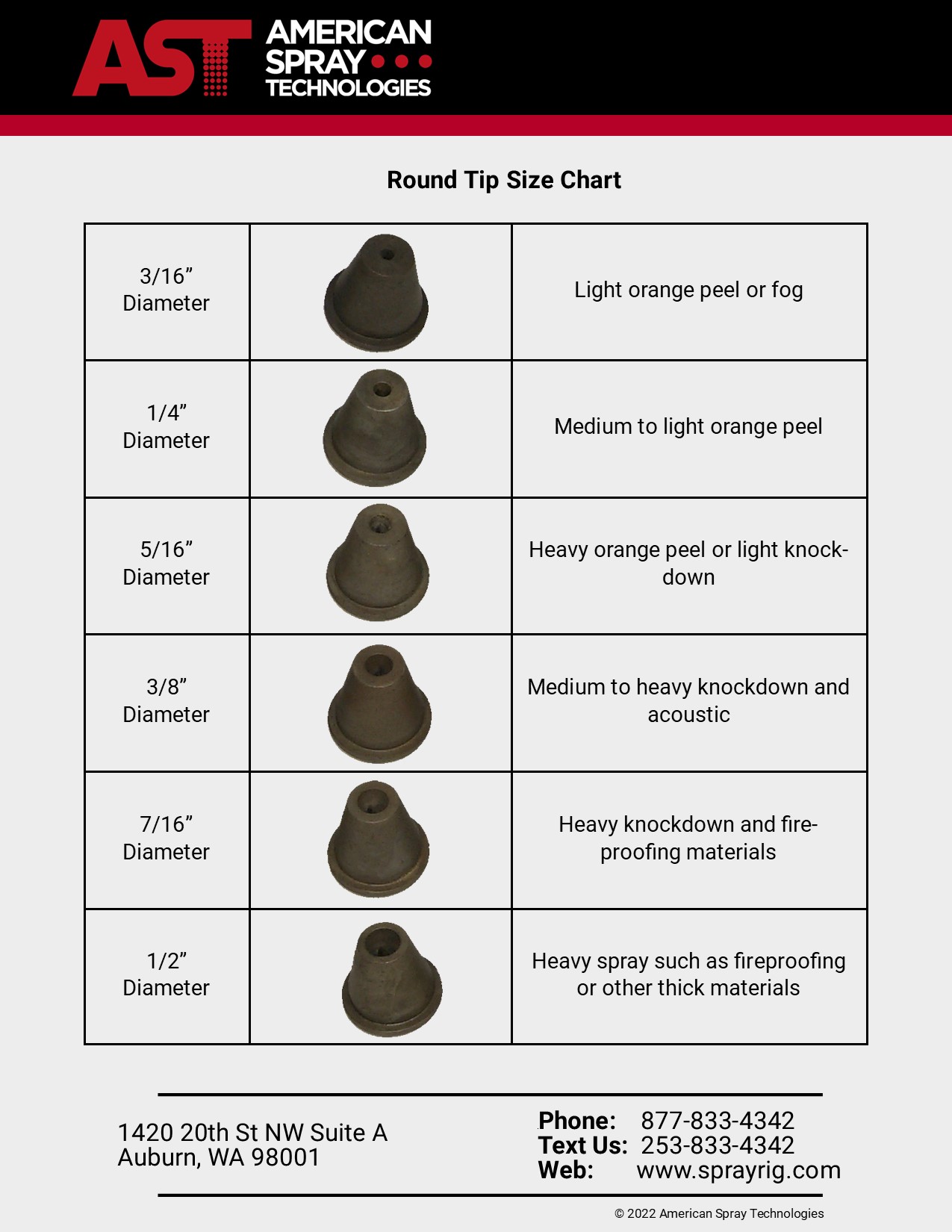

What size tip should I use?

What type of engine oil should I use?

For Kohler gas engines use 10W30 detergent. For extreme cold or hot weather see the manufacturers operating manual.

What type of compressor oil should I use?

For Champion compressors, use 30 WT Non-Detergent.

For Quincy and Atlas-Copco compressors, use 30 WT Non-Detergent 80 degrees and over and use 20 WT Non-Detergent 79 degrees and under.

What type of hydraulic oil should I use?

Use Chevron Hydraulic Oil AW ISO 68 or equivalent.

How often should I perform a tune up on the machine?

Your engine and compressor operating manuals are your best source for detailed service advice. This guide should be used as a quick reference or reminder. Drywall spray rigs operate in a dusty environment and require special attention for the maintenance of fuel, air and oil filters and fluids. Every Big Rig is used differently and the maintenance schedule should reflect that use. If you spray daily and mix in an enclosed truck you need to service your machine more often than someone who sprays twice per week and mixes outdoors.

| 5-Hour Break In: | Break-in for a new Kohler engine requires an oil change after the first 5 hours |

| Daily service: | Check oil level in engine, compressor and hydraulic tank |

| Weekly Service: |

Clean (shake out) Kohler engine air filter and compressor filter Check compressor and engine drive belts Inspect rig for any unsafe condition or loose parts Clean texture strainer |

| 25 Hour Service: |

All of the above plus: Inspect rig for loose parts and unsafe conditions Inspect trailer lights, safety chains and tires |

| 50 Hour Service: |

Change Kohler engine oil. We recommend this more often than the Kohler recommendation of 100 hours because of the dusty operating environment of a spray rig. Break-in oil change for a new diesel engine. Then every 100 hours. |

| 100 Hour Service: | Same as 25 and 50 hour service plus: Inspect mixer chain tension – adjust as needed Inspect compressor drive belts – adjust as needed Change compressor oil Inspect hydraulic oil and top off – replace oil and filter if dirty Change Diesel engine oil – This is more often than the manufacturer recommendation of every 200 hours because of the dusty operating environment of a spray rig. Service wheel bearings Replace fuel filter Check hoses for wear and fraying |

| 200 Hour Service: | Replace Kohler engine spark plugs – for 18 to 25 HP |

| 500 Hour Service: |

Same as 25, 50 and 100 hour service plus: Replace hydraulic oil filter and lube mixer bearings |

When should I change my stator tube and/or rotor?

Stator tubes may need to be changed for a few reasons. If your pump is losing pressure or you don’t have the same pressure you used to, or no pressure at all, your stator tube may be worn out. Stator tubes may also need to be replaced if the rubber is damaged or some foreign debris has been pumped through the stator tube. There are no hard rules for the timeline in which a stator tube may need to be replaced as it will depend on your use of the machine.

Rotors may need to be replaced if there is any damage to the rotor or if the connecting interface on the back of the rotor is wearing out or stripping out. If the connection between the rotor and connecting rod is loose, the rotor may be at fault.

To troubleshoot any of these issues, talk to our tech support team by calling or texting 253-833-4342.

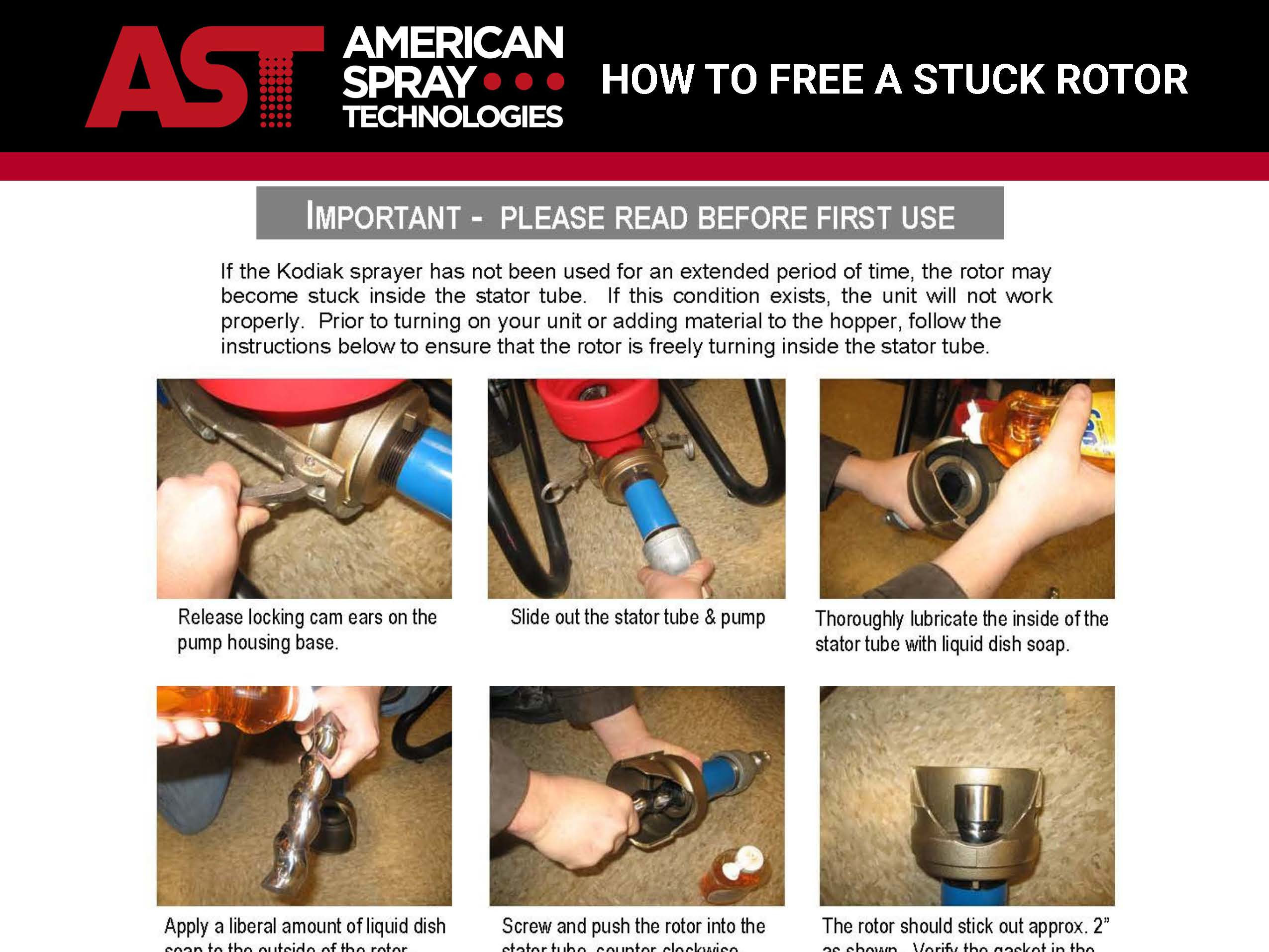

What should I do if my rotor is stuck?

Pumps with new stator tubes or pumps that have been sitting inactive for long periods of time may be stuck when initially starting the pump. This is due to the rubber in the stator tube gripping the rotor. To break the rotor free, a wrench can be used on the nut at the end of the rotor. This manual rotation of the rotor typically provides enough force to break the rotor free.

Watch this video to see a demonstration of this process:

What is the normal operating RPM for the Kohler engine while spraying or mixing?

Normal operating range for a Kohler engine while mixing or pumping texture is 3000-3200 RPM.

How many hours are on my rig?

The RPM gauge on your engine is also an hour meter. When the engine is running, the display shows RPM. Once you shut down the machine, the gauge will show the total hours and minutes the engine has been ran.

Where can I find the VIN number for my trailer?

The VIN number is located in two places.

- It is stamped on the driver side of the frame on the front of the trailer. Check for the VIN stamp on the driver side of the tongue.

- It is on the VIN label located on the driver side back of the tank.

When was my trailer manufactured?

You can find the manufacturing date of your trailer on the VIN label located on the driver side back of the tank. If this label has been obscured, you can contact us and we can look up the date for you.

What kind of mud can I mix in the tank?

Any box (premix) or bag (powder) spray texture can be mixed in the tank.

What is the price of a big rig?

For big rig pricing, call or text 253-833-4342 or request a quote using Build A Rig.

What is the price of a Kodiak M2?

For Kodiak pricing, call or text 253-833-4342.

Where can I find the serial number on my Kodiak?

Kodiak serial numbers are located on the side of the electric motor.