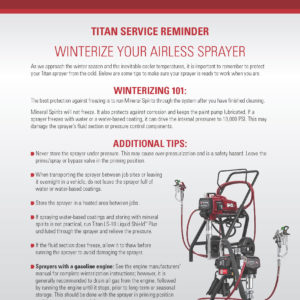

Winterizing Your Airless Sprayer

November 21, 2023Prepare your airless sprayer for the winter months with Titan’s quick guide on winterization. ❄️ Download The Flyer As temperatures... View Article

Prepare your airless sprayer for the winter months with Titan’s quick guide on winterization. ❄️ Download The Flyer As temperatures... View Article

As a dedicated drywall texture contractor, you’re always looking for ways to improve your business’s bottom line. We have some... View Article

Freezing temperatures can add some complication to your spray day. Cold weather can affect the material being sprayed and in... View Article

The AST catalog is a great resource for learning about our product line and for browsing spare parts. You can... View Article

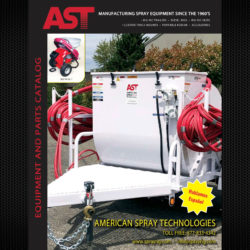

AST offers two platforms for gas-powered spray rigs: Trailer-mounted and skid-mounted. Neither platform is universally better than the other, but... View Article

When designing the Kodiak M2, we baked the performance of a big rig into a smaller package. The Kodiak uses... View Article

The right texture spray rig is an indispensable part of your business. A spray rig allows for fast mixing, easy... View Article

You’ve decided on your platform, power pack, tank size, and hose set. What other options are available? AST has a... View Article

Back in the 1990s, a contractor in Alaska contacted us needing big rig performance in a package that could fit... View Article

How do AST pumps work? AST rigs use rotor stator pumps, also known as progressive cavity pumps, because of their... View Article

Get up to date details on our products & services.